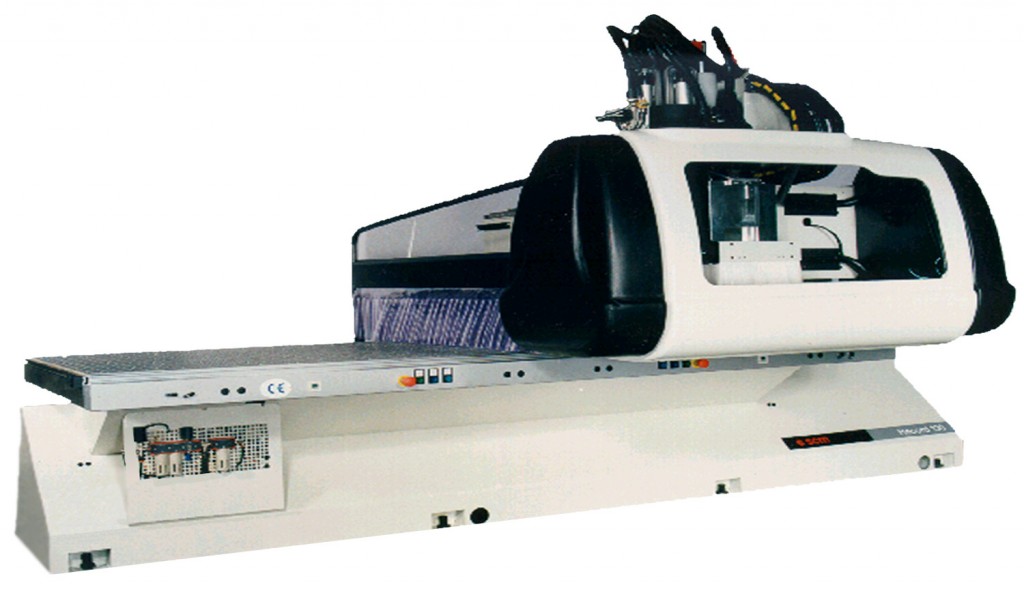

Routech 130 – CNC Flatbed Router

Our largest CNC router. It has two 10hp motors with ceramic bearings which allows it to cut two parts at a time. It is also unique because it has two 5′ x 5′ beds that move together or independently. If the two beds are “ganged” together it can hold up to a 5′ x 10′ sheet of board. It’s great for making slotwall and smaller parts since it can cut 2 at a time.

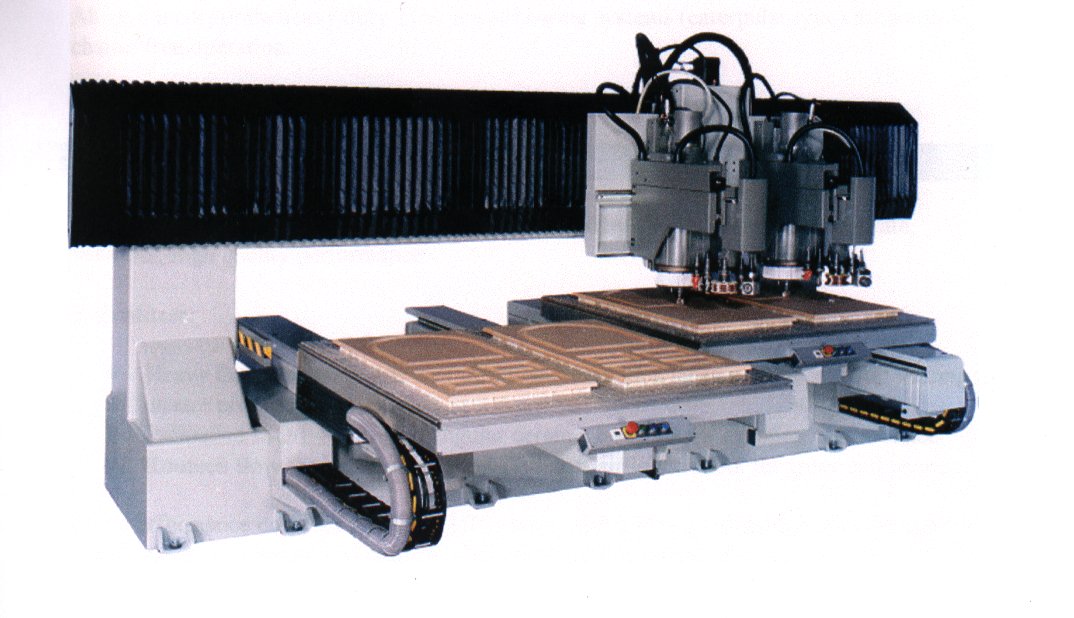

Routech 250 CNC Twin Head Router

Our largest CNC router. It has two 10hp motors with ceramic bearings which allows it to cut two parts at a time. It is also unique because it has two 5′ x 5′ beds that move together or independently. If the two beds are “ganged” together it can hold up to a 5′ x 10′ sheet of board. It’s great for making slotwall and smaller parts since it can cut 2 at a time.

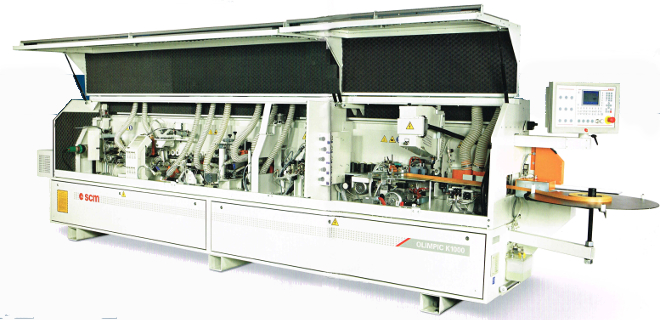

K1000 Inline Edgebander

At over 19′ long this machine automatically applies the finished edge to panels. For example if you have a plywood shelf you see the ply’s in the plywood when it’s installed. By edgebanding the front edge makes it look finished. This machine can apply veneer, PVC, plastic laminate and even solid wood. It can also automatically radius the edge on the top and bottom if the edgebanding is thick enough. It does all of that at a speed over 50′ per minute.

M80 Contour Edgebander & Trimmer

The Inline Edgebander is fast for edgebanding straight edges. Many times curved or circular parts need to be edged. Then we use this contour edgebander. It’s not as fast as the inline edgebander since it requires more operator skill. The edging also needs to be trimmed on a separate machine since this type of edgebander doesn’t trim the top and bottom edge automatically.

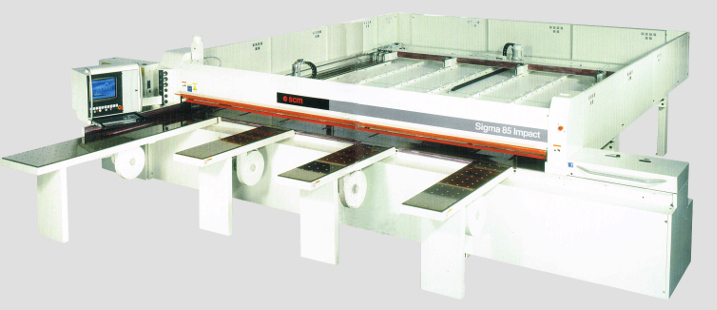

Sigma Impact Panel Saw

By far the largest machine in the shop. It covers an area of 550 sq ft. It can hold sheet sizes up to a 5′ x 12′ . Where the routers can cut 1 sheet at a time, this saw’s advantage is that it can cut a stack of up to 5 sheets of 3/4″ at time or 15 sheets of 1/4″. Also the cut patterns can be programmed from the office and sent out to the machine.

Table Saw

A table saw is one of the most dangerous tool in the shop. This table saw has a high tech feature that greatly reduces accidents. If a finger comes in contact with the blade while it is spinning the devices senses the touch and immediatly presses a chunk of solid aluminum into the bottom of the blade stopping it in a fraction of a second, while at the same time retracting the blade under the table so it no longer protrudes. It all happens in about the same amount of time as an airbag in a car.